Future proofing smart manufacturing with edge AI

The Manufacturing Industry is at a Crossroads

The manufacturing industry is undergoing a seismic shift as it embraces Industry 4.0 and the potential advantages of digital transformation. Once characterized by rigid processes and slow-moving supply chains, factories are now expected to be agile, responsive, and sustainable. The pressure to increase efficiency, improve product quality, and reduce costs while navigating a complex global economy has never been greater. Industry 4.0 offers a roadmap for transformation, but its realization hinges on overcoming significant hurdles.

A shortage of skilled talent, the delicate balance between cost reduction and quality enhancement, the integration of new technologies within constrained budgets, and building resilient and agile supply chains in an increasingly volatile global market are just a few of the complexities manufacturers face. At the heart of addressing these challenges lies edge AI. By decentralizing processing and bringing intelligence closer to the data source, edge AI empowers manufacturers to make rapid, data-driven decisions that optimize operations and increase efficiency.

Gaining an Edge AI Advantage in Manufacturing

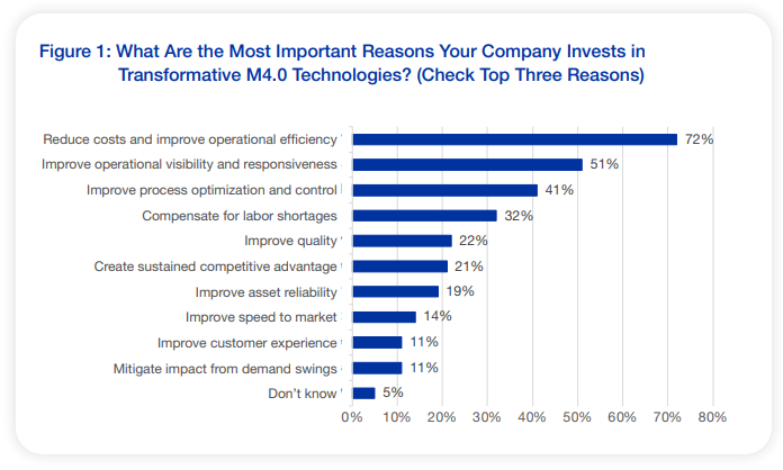

Figure 1. Source: National Association of Manufacturers (NAM)

A 2023 survey conducted by the NAM’s Manufacturing Leadership Council revealed key reasons why manufacturers are investing in AI (Figure 1). Executives from around the globe cited cost reduction, improved operational visibility, and process optimization as primary drivers for adopting Industry 4.0 technologies, including artificial intelligence. By leveraging edge AI, manufacturers can accelerate these goals through real-time data analysis, achieving immediate process adjustments, enhanced quality control, and increased operational efficiency.

Predictive Maintenance

Edge AI analyzes real-time sensor data to predict potential equipment failures, allowing for proactive maintenance and extended equipment lifespan. By utilizing low-bandwidth, inexpensive cameras, manufacturers can implement predictive maintenance without disrupting operations.

- Image analysis of machinery components: Identifies wear and tear through visual inspection of parts.

- Thermal imaging: Detects overheating components that could lead to failure.

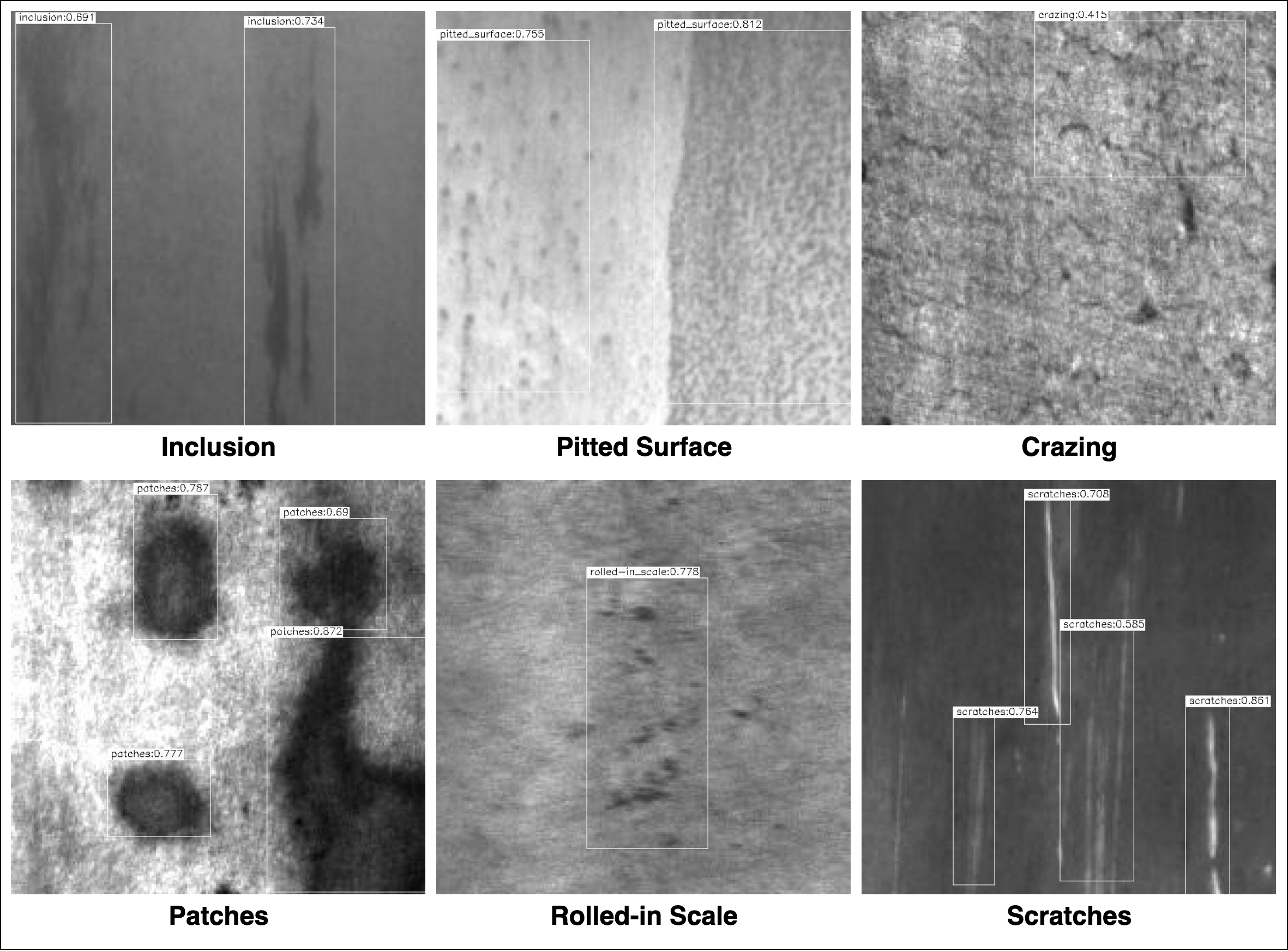

Quality Assurance

Implementing edge AI in quality control processes can significantly enhance product quality, reduce defects and ensure products meet stringent standards. By analyzing real-time data from production lines, edge AI can detect anomalies, identify root causes, and implement corrective actions immediately, minimizing waste and rework. This can be achieved by deploying AI directly on manufacturing robots or integrating it into sensors and cameras.

- Defect detection: Identifies flaws or imperfections in products using image analysis.

- Product assembly verification: Ensures products are assembled correctly through visual inspection.

Process Optimization

Edge AI allows manufacturers to achieve process optimization mobility by bringing intelligence directly to the shop floor. By analyzing data from sensors and equipment in real-time, manufacturers can identify inefficiencies and bottlenecks with unparalleled agility. This mobility enables rapid adjustments to production lines, reducing waste and energy consumption

- Object tracking: Monitors product movement on assembly lines to identify bottlenecks instantly.

- Visual inspection of raw materials on-the-spot: Ensures incoming materials meet quality standards without delays.

Supply Chain Resilience

McKinsey reports that successfully implementing AI-enabled supply-chain management has enabled early adopters to improve logistics costs by 15%, inventory levels by 35%, and service levels by 65%, compared with slower-moving competitors. Edge AI provides real-time visibility and insights into the supply chain, giving manufacturers the ability to anticipate disruptions and optimize inventory levels.

- Barcode and QR code scanning: Tracks product movement through the supply chain.

- Image-based inventory management: Accurately counts and categorizes inventory items.

Worker Safety

Edge AI can significantly enhance worker safety by providing real-time monitoring and analysis of workplace conditions. By deploying sensors and cameras throughout the factory, manufacturers can identify potential hazards and implement preventive measures.

- Worker monitoring: Tracks worker movements to identify potential safety risks, such as proximity to hazardous equipment.

- Environmental monitoring: Detects hazardous conditions like gas leaks, excessive noise, or extreme temperatures.

- Equipment monitoring: Identifies abnormal equipment behavior that could lead to accidents.

- Emergency response: Triggers alerts and activates emergency protocols in case of accidents or incidents.

Virtual Reality (VR) Training for Enhanced Safety

To complement these real-time safety measures, VR training can provide immersive experiences to equip workers with the skills to prevent and respond to hazards.

- Hazard identification: Train workers to recognize potential safety risks in virtual environments.

- Emergency response simulations: Prepare workers for emergency situations, such as fires, equipment malfunctions, or chemical spills.

- PPE usage: Teach workers the correct use of personal protective equipment (PPE) in various scenarios.

- Ergonomic training: Demonstrate proper body mechanics to prevent musculoskeletal injuries.

Technical Advantages of Edge Computing

Edge computing brings data processing and storage closer to the source of data generation, offering several key benefits:

- Low latency: By processing data closer to the source, edge computing reduces latency, empowering real-time decision-making and control.

- Improved responsiveness: Edge devices can react quickly to changes in the environment, enhancing system agility and adaptability.

- Increased reliability: Edge computing reduces reliance on network connectivity, making systems more resilient to disruptions.

- Data privacy and security: Processing data locally minimizes the risk of data breaches and ensures compliance with data privacy regulations.

The Potential ROI of Edge AI Implementations

According to McKinsey, companies using AI have witnessed cost savings and revenue growth. 16% of those surveyed noticed a 10-19% decrease in costs, whereas 18% saw a 6-10% increase in overall revenue. Edge AI offers significant return on investment (ROI) opportunities:

- Increased productivity: Edge AI-driven automation and optimization can boost production efficiency, leading to higher output and revenue.

- Cost reduction: By minimizing downtime, reducing waste, and optimizing energy consumption, edge AI can generate significant cost savings.

- Improved product quality: Enhanced quality control through edge AI can reduce rework, scrap, and warranty claims, leading to increased customer satisfaction and revenue.

- Faster time-to-market: Edge AI eliminates the need to transfer large datasets to the cloud, significantly reducing development time and costs. With streamlined development and testing processes, businesses can introduce new products and services more quickly, gaining a competitive edge. Deploying AI models on edge devices early in the product lifecycle allows for real-world testing and validation, providing valuable feedback for product improvement based on changing market conditions and customer preferences.

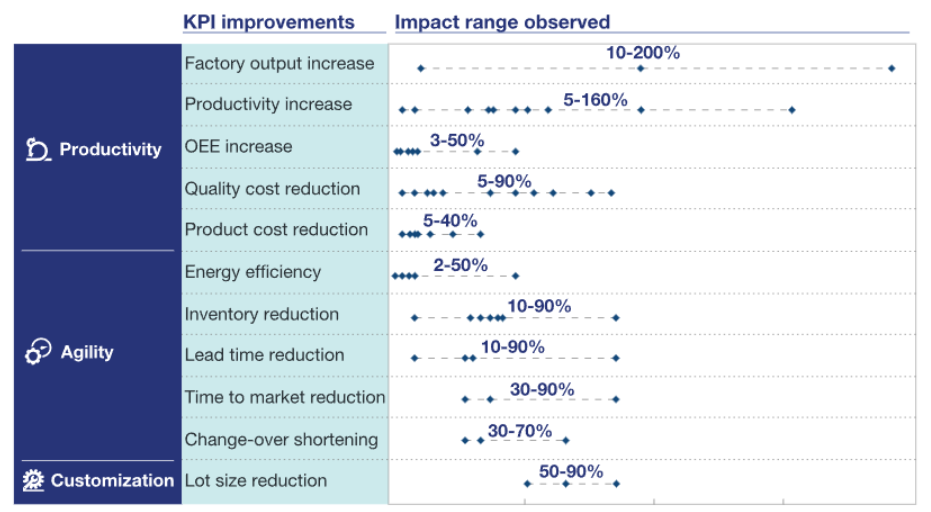

To put these potential benefits into perspective, consider the findings of a McKinsey study on lighthouse factories (Figure 2). These leading-edge manufacturing facilities have achieved impressive results by using advanced technologies, seeing productivity increases of 5-160%, as well as significant reductions in quality costs (5-90%) and product costs (5-40%).

Figure 2. Source: World Economic Forum and McKinsey & Company lighthouse site analysis

The Future of Manufacturing is at the Edge

Edge AI is poised to revolutionize the manufacturing industry by addressing critical challenges and unlocking new opportunities. By enabling real-time decision-making, optimizing operations, and enhancing product quality, edge AI is becoming a cornerstone of smart factories.

Latent AI can help manufacturing companies overcome the complexities of edge AI and drive significant business value. Latent AI Efficient Inference Platform (LEIP) empowers developers to rapidly build, optimize, and deploy AI models to edge devices, overcoming the traditional hurdles of complexity and time-to-market.

To learn how Latent AI can help your organization achieve its goals visit latentai.com or contact mlops@latentai.com today.